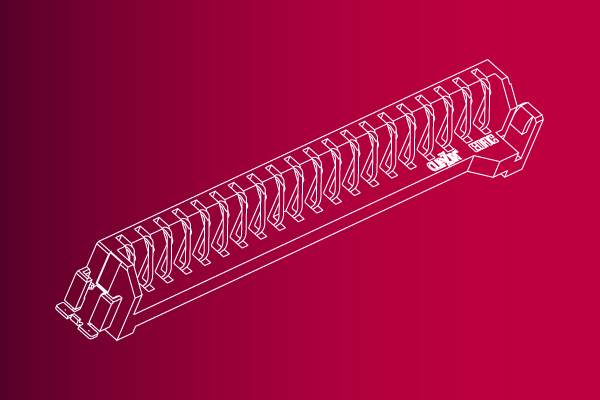

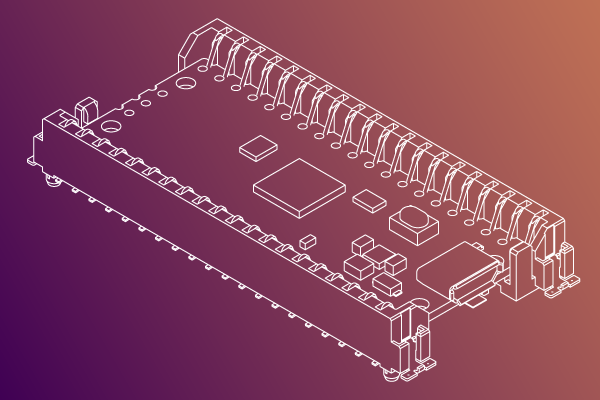

The innovative SMT connector that enables tool free mounting of one PCB module on another! Perfect from use in prototyping to production. PCB modules just clip-in!

Mounts leading compute modules

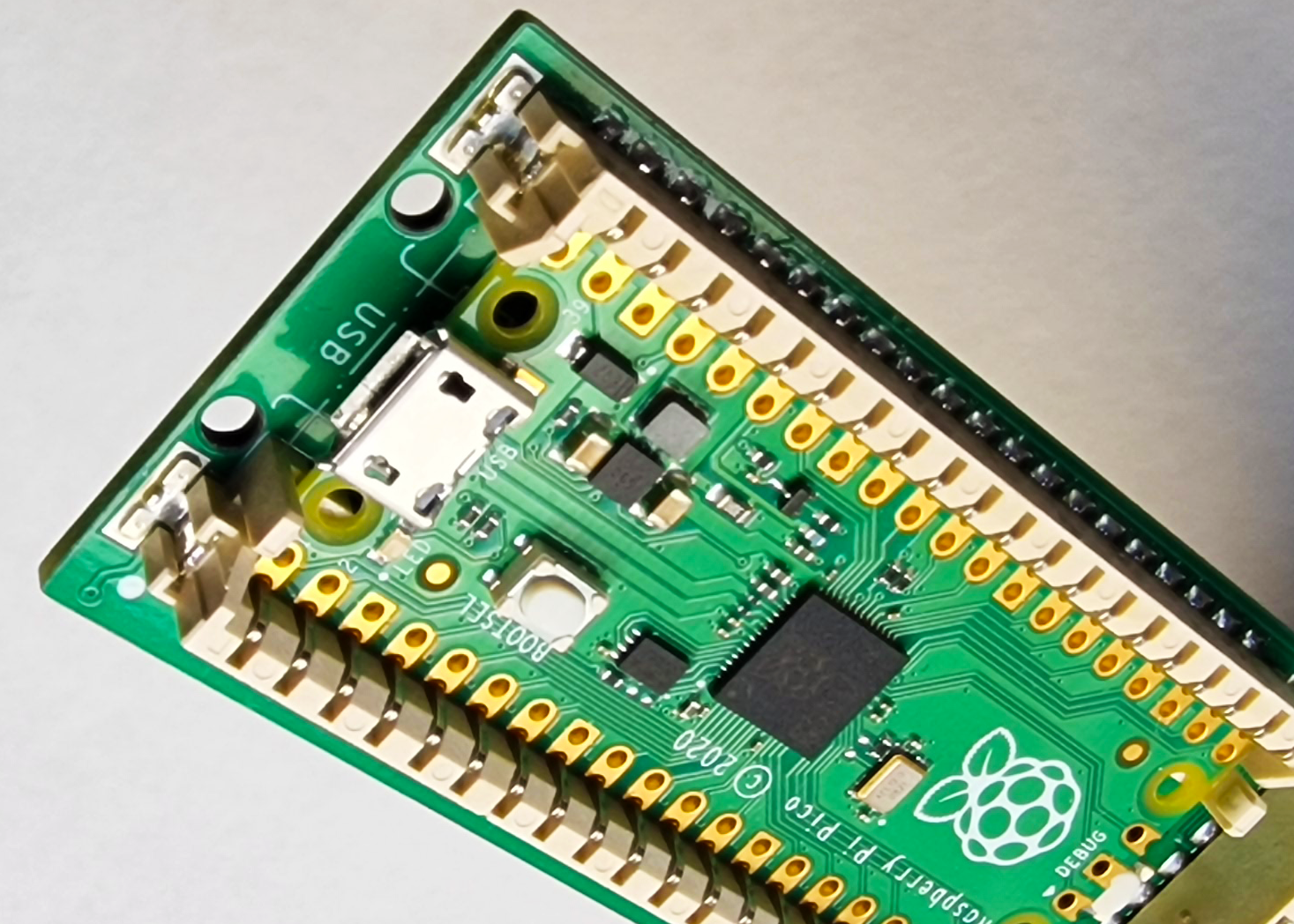

Compatible with a growing ecosystem including Raspberry Pi® Pico and Arduino® Nano

Give your product flexibilty

Perfect for clipping in interchangable comms, sensor or other modules.

Simplier, cheaper manufacturing

Connects via module PCB edge contacts so nothing to solder to the module.

No more through-hole

Eliminates need for through-hole soldering and the need to solder fiddly header pins

PCB modules that just need to be clipped-in

Easily mix and match modules!

Need to send data in different enviroments? Clip-in the pre-certified radio specific to your region. Choose from the growing range of pre-certified WiFi, Bluetooth, BLE, Cellular and LoraWan modules joining the ecosystem, or build your own.

Need the flexibility of using different sensors? Clip-in the sensor or actuator module that meets your needs.

Clipzin makes it easy to mix and match modules and change them as required. Great for developing in the prototyping stage, great to offer flexibility and configurable options in the production stage.

Design reuse of entire subsystems and assemblies easier parts sourcing - interchangable modules that can be swapped out for different performance or availablity make use of pre-certified IP, faster development times can choose the modules you need and clip into the base. Sell in multiple regions? Tailor your product configurable without tiying stock up soldered configurations costly building multiple versions Clipzin is surface mount -- compatible with automatic assembly pick and place

Efficient Production

Reduce costs of building your modules

Modules clip in without soldering. This means no costly through-hole soldering of header pins. Furthermore, Clipzin™ connects the the castellated edge connections on PCB modules, meaning a connector only needs to be fitted to just the base board. This allows very cost effective production of PCB modules, without the cost of a connector, or associated cost of soldering it.

* promotes design reuse, without the need to fit a connector, make single sided modules, using castellated PCB terminals mean no cost for sub-module manufacture